Biogas use in Reconstruction

Practical Action

Using Biogas units to reduce waste

In a post-disaster scenario it is likely that toilet provision will

be limited to pit latrines, at least until more advanced

solutions can be implemented. The pit can fill up quickly,

which can easily lead to pollution, contamination and

unsanitary conditions unless either a new pit is dug or the

existing pit is emptied. In rural settings it is generally easier

to construct a new latrine, but this is probably not possible in

a confined urban setting.

Therefore, in urban reconstruction contexts there is a

requirement for latrines to be emptied as they become full of

waste sludge. Currently this is dominated by manual methods,

which are inefficient and expose the operators to severe

health risks. Practical Action’s technical brief Pit Emptying

Systems examines some of the advanced mechanical

emptying solutions that are being developed.

Another option is to combine biogas digester technology with

the latrines; this gives the opportunity to control human waste

and reduce pollution, whilst providing useful fuel and by-

product in the process. Despite the several benefits that this

can achieve, there are certain barriers to implementation that

must be considered, including ‘soiling-up’ (a hard

irretrievable layer grows with use), social acceptance and

logistical constraints. Refer to the Practical Action technical

brief Using Biogas Technology to Solve Pit Latrine Waste

Disposal Problems for a detailed study on this.

Figure 4: Pit latrines in the

Kibera informal settlement

(slum) in Nairobi, Kenya.

Photo: Karen Robinson /

Practical

Action.

A combination of both shallower pits and permanent suction pipes could be beneficial to solving

fluidity/emptying issues and soiling up in pits, but also provide hygiene benefits to the emptier

and fresher feedstock for the digester. The critical factor when assessing digester placement is

space, because without it there will be no other problems. Regarding pressure issues, the use of a

storage vessel is proposed rather than just a comprehensive maintenance program because it

provides the user with the ability to alter the pressure, however further assessment would be

required.

The issues regarding technology when using biogas to reduce

waste can be split into collection, haulage, disposal and

treatment:

Collection: the sludge will be partially degraded upon emptying

therefore decreasing the maximum methane yield. This means,

to make the system feasible the frequency of pit emptying will

have to increase. Pit emptying frequency is inversely

proportional to the operational life of the pit. Dismantling is

often required when emptying a pit.

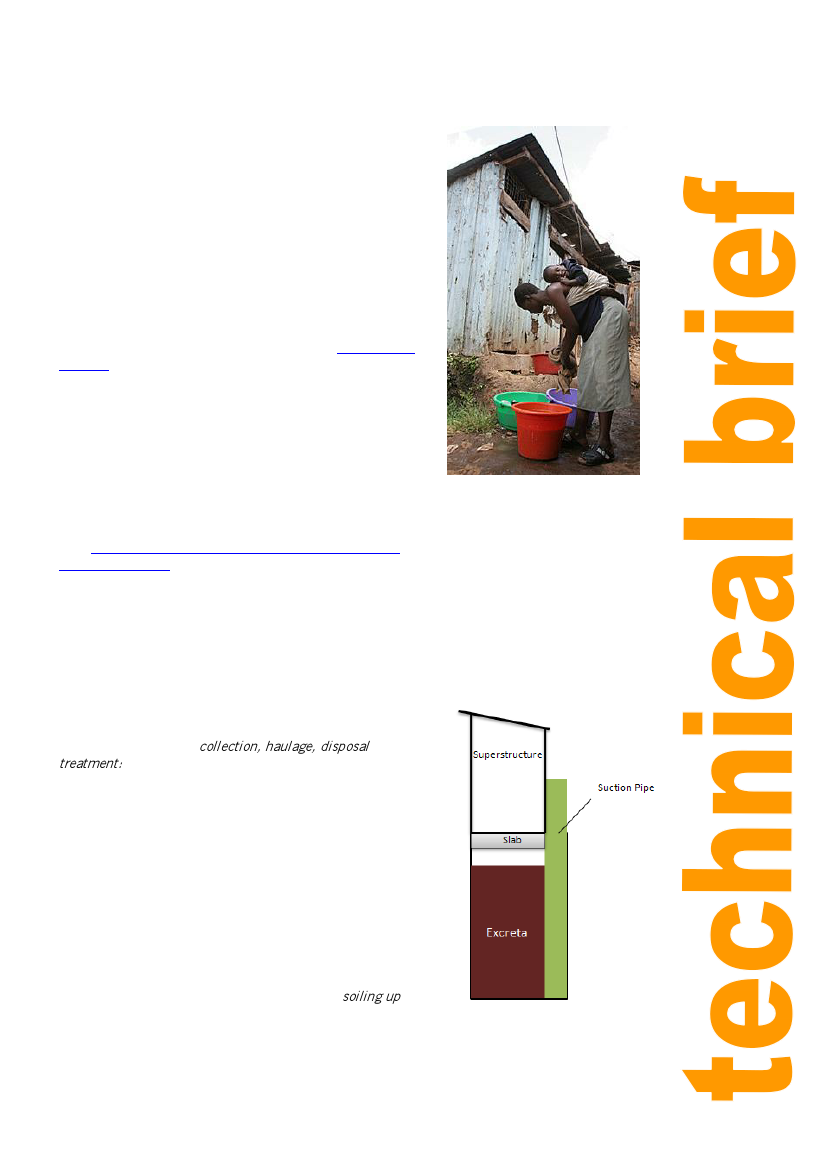

A solution proposed is to fit an in-situ pipe to the pit that has

an exit outside the super structure (Figure 5). This addition will

limit the disruption caused by emptying as well as making the

whole process more hygienic because the hose will no longer

have to be dropped into the faeces. The addition will also help

deal with the problems regarding viscosity and soiling up in pits

because emptying will happen from the bottom and water can

be added through the pipe to decrease the viscosity.

Figure 5: A diagram conveying

the use of an in situ pipe.

Source: Practical Action

7